MANUFACTURING

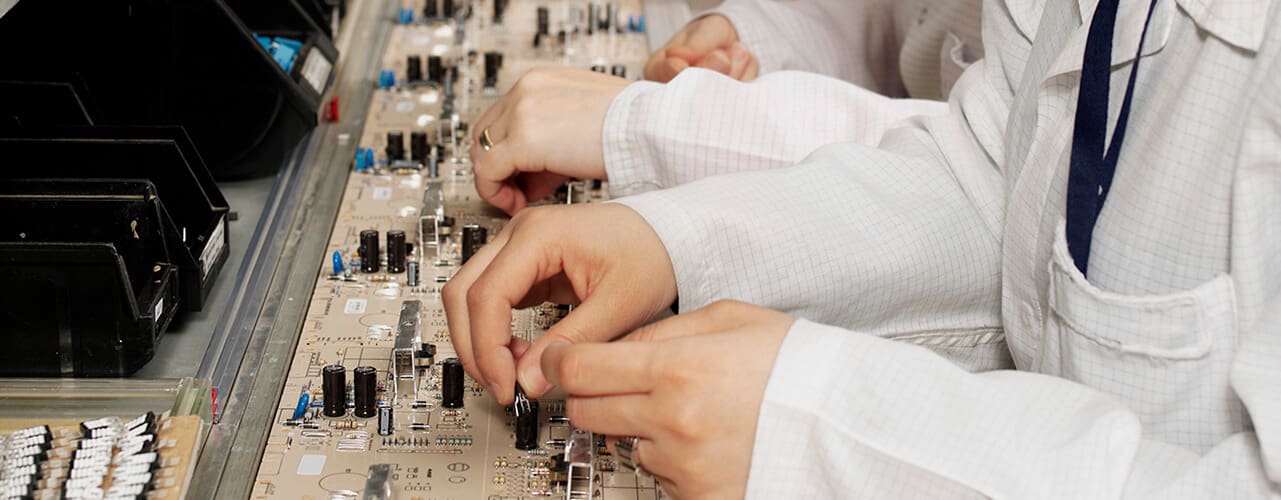

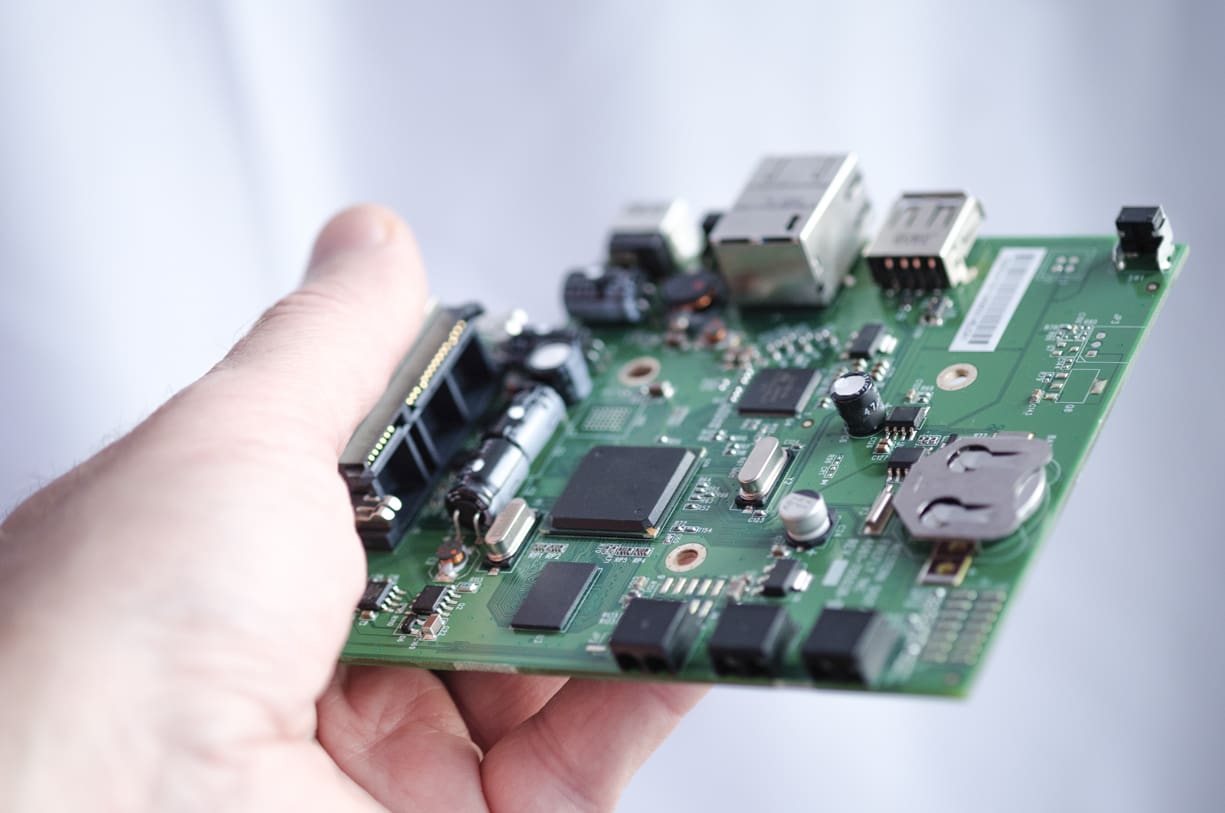

MEDCO approaches every project with today’s advanced process planning, production methods, and commitment to quality. These methods are applied to surface mount, through-hole manufacturing, hand assembly, procurement, and design. We understand that every product represents unique production challenges, and that’s why we are continuously upgrading our equipment and facility to ensure that you will receive your products on time and functioning according to your exact specifications.

We leverage our 39+ years of manufacturing experience to develop scalable production methods. Our engineers work to develop customized final assembly and packaging solutions for all production volumes. MEDCO’s facilities, equipment, staffing, and training allow us to be flexible concerning your product complexity. We are small enough to provide a highly personalized approach, yet large enough to address your production needs.

Our production staff receives ongoing training and certification on all aspects of the electronic assembly process. MEDCO’s success is linked to yours, and we treat every product we manufacture as if our name were on the label. Our dedication to achieve total customer satisfaction is our number one priority. No matter what your requirements may be, MEDCO is committed to the quality, service, and professionalism you expect from a leader.

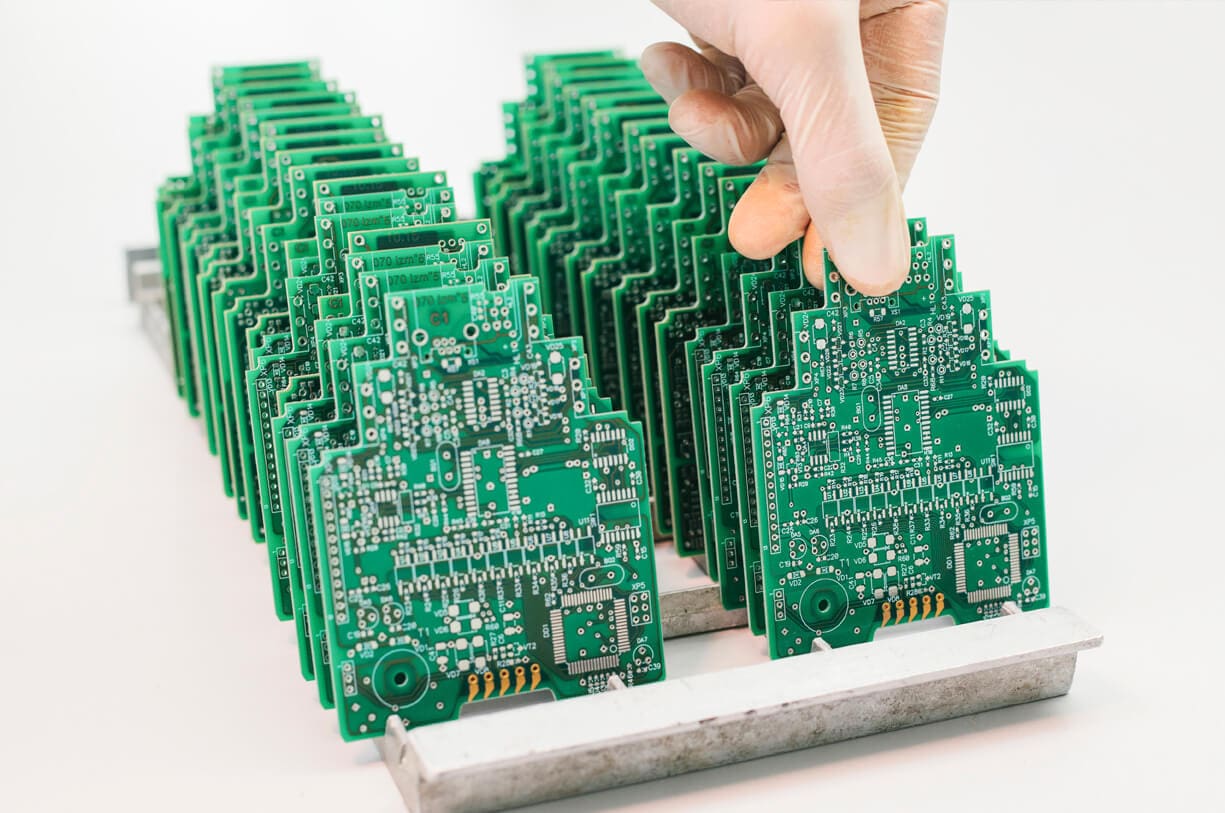

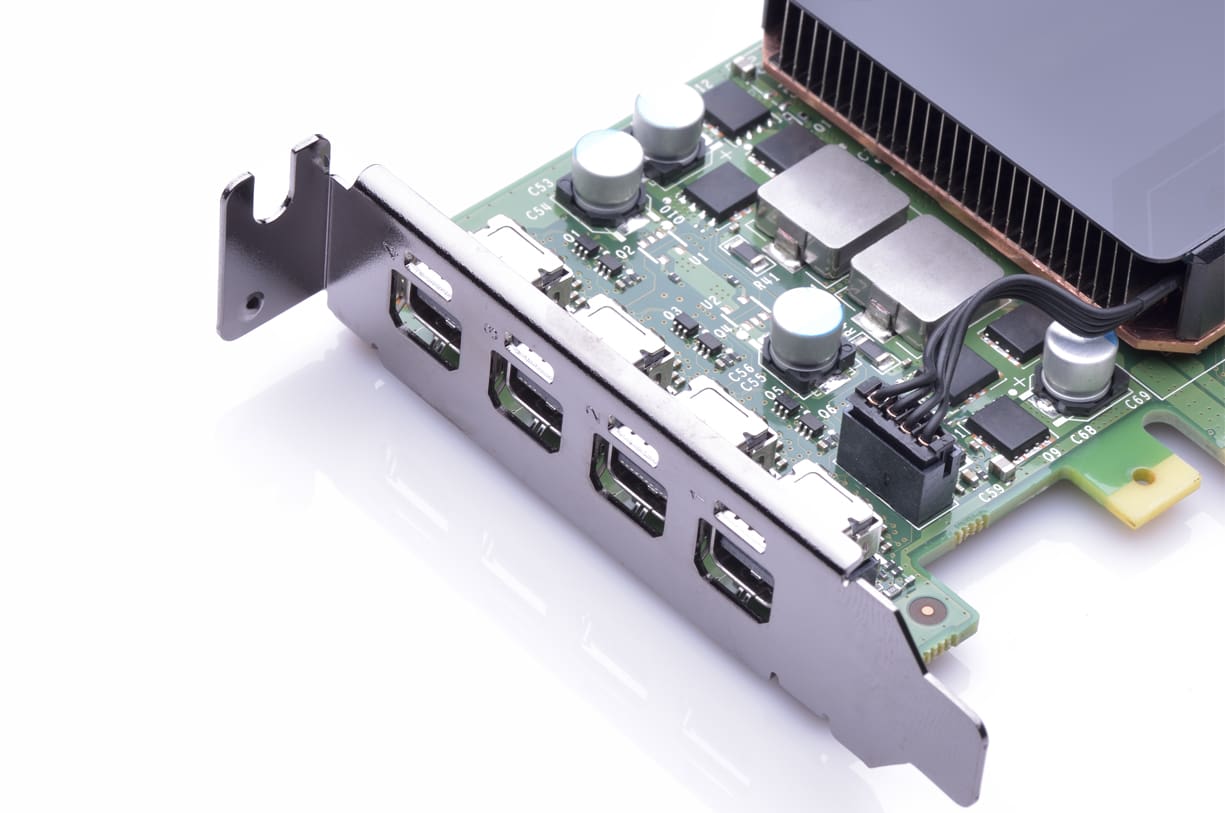

SURFACE MOUNT TECHNOLOGY (SMT)

– Precision placement of components: fine pitch QFP, BGA, PLCC, SOIC/SOLICs

– Quick adjustment to panels large as 18″x24″

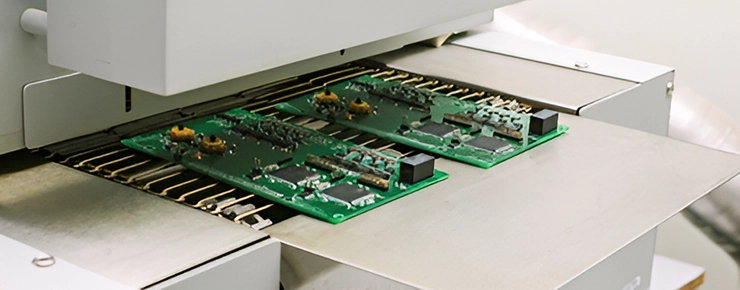

THROUGH-HOLE TECHNOLOGY (THT)

– Wave/Selective Solder

– Rigid, Rigid-Flex, Flex & Bonded Assemblies

– Protection of Circuits: Conformal Coating and Staking