PRODUCT VALIDATION & COMPLIANCE

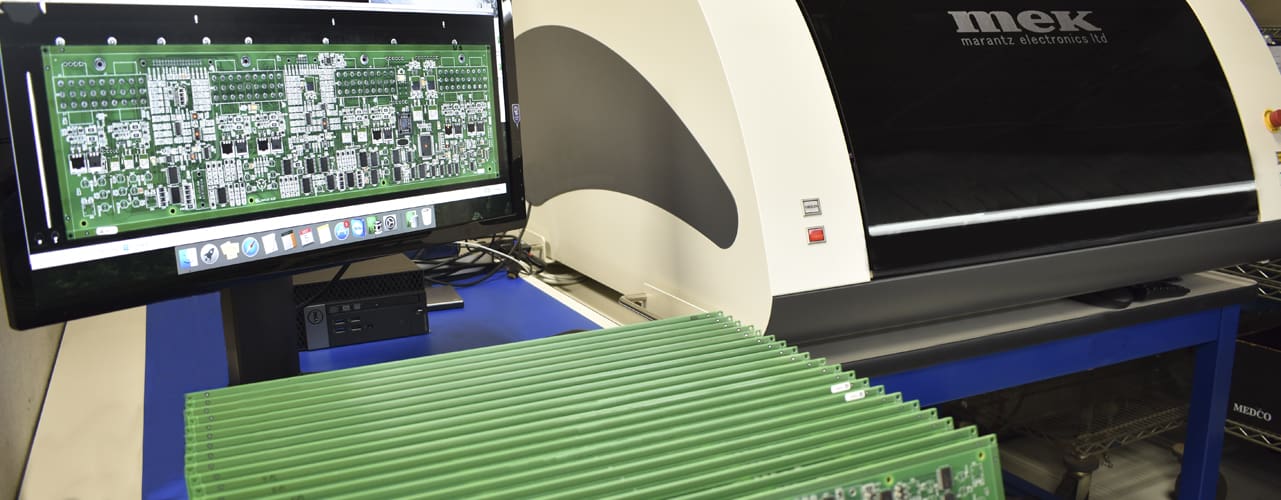

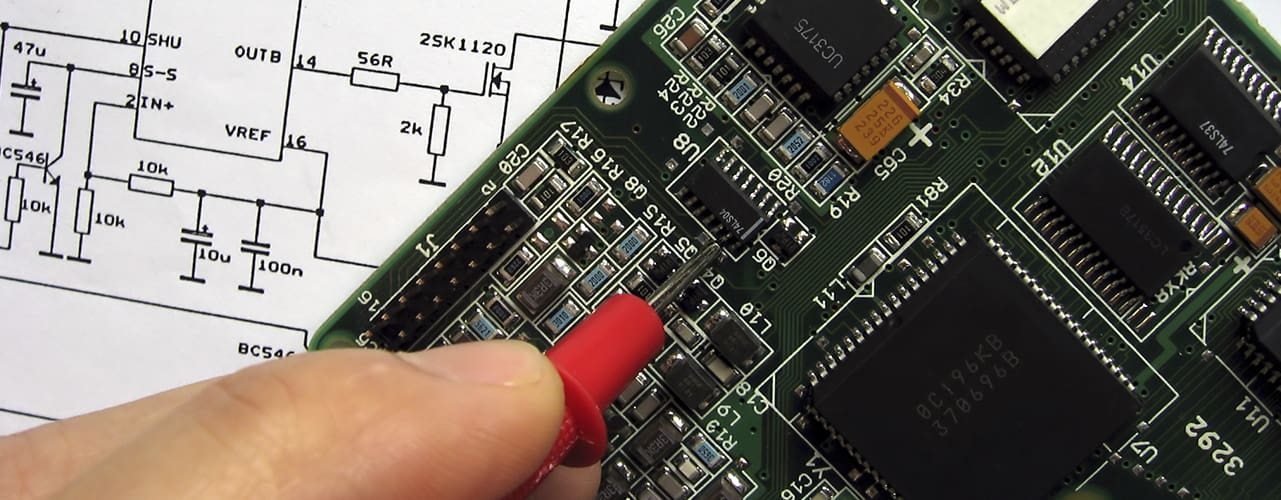

Based on our customers' needs, we provide an array of assembly methods, testing solutions, and quality guidelines. MEDCO offers a warranty to ensure the quality of your products.

MEDCO built its first RoHS-compliant Printed Circuit Board prototype assembly over fifteen years ago. We are ready to assemble any RoHS-compliant assemblies that you require.

We demonstrate our commitment to quality, productivity, and customer satisfaction by following IPC guidelines to protect our products from ESD.