PRODUCT VALIDATION &

COMPLIANCE

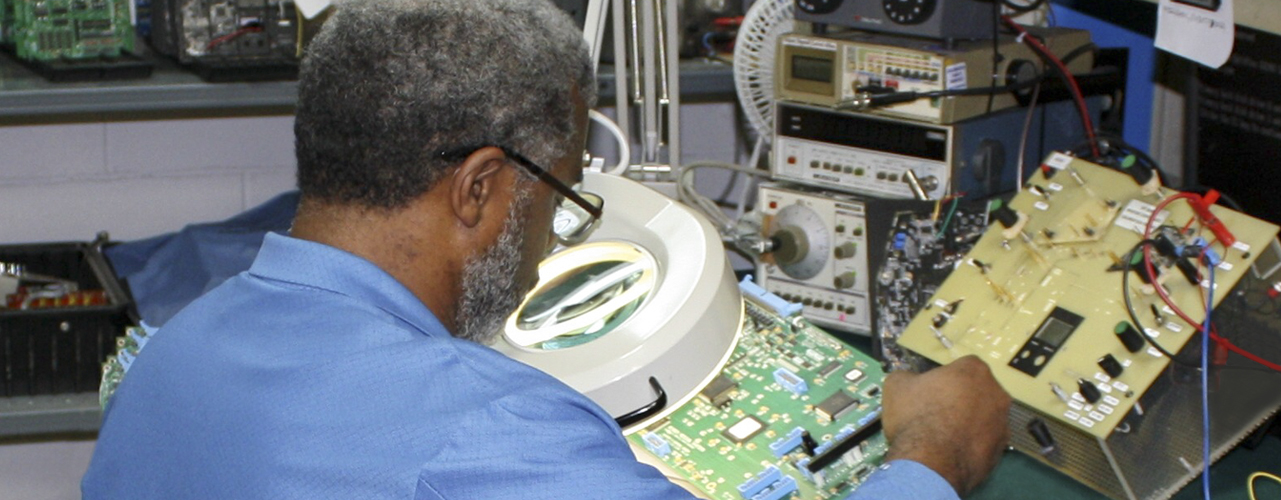

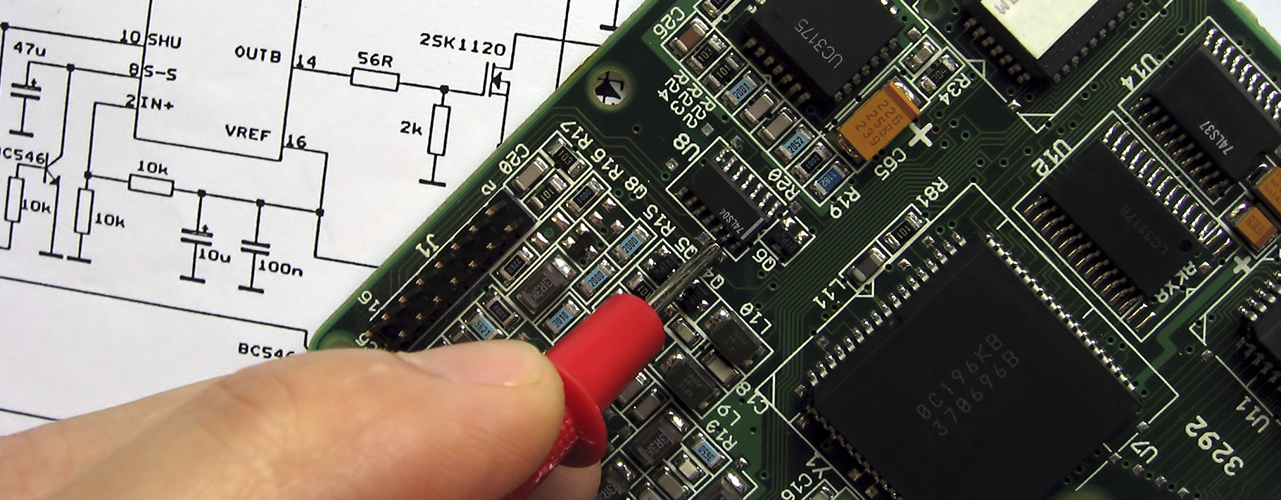

Based on our customer’s needs, we provide an array of assembly methods, testing solutions, and quality guidelines. MEDCO offers a warranty to ensure the quality of your products.

MEDCO built its first RoHS compliant Printed Circuit Board prototype assembly over fifteen years ago. We are ready to assemble any RoHS compliant assemblies that you require.

We demonstrate our commitment to quality, productivity, and customer satisfaction by following IPC guidelines to protect our products from ESD.

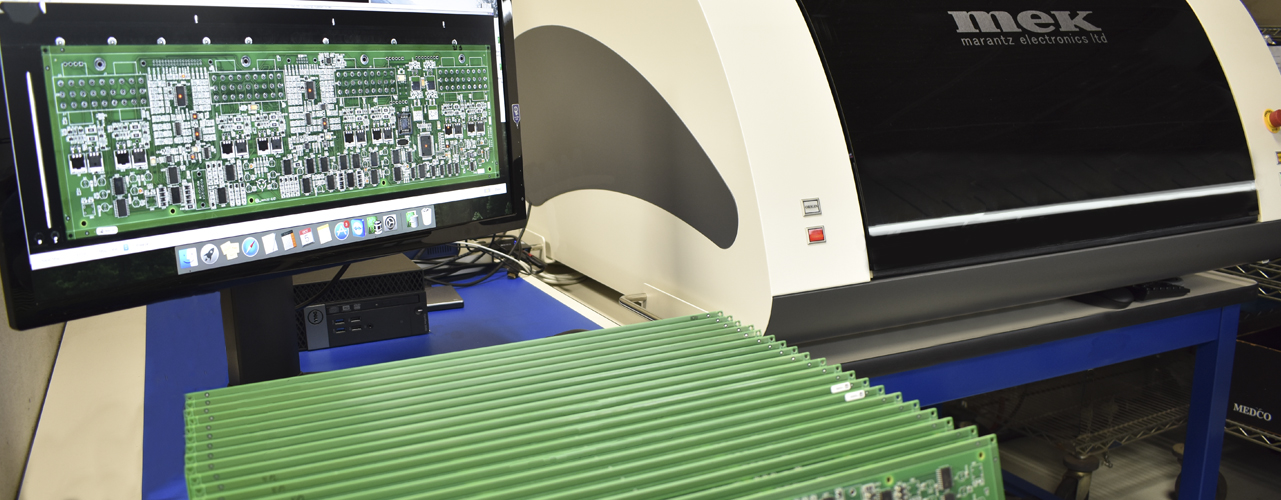

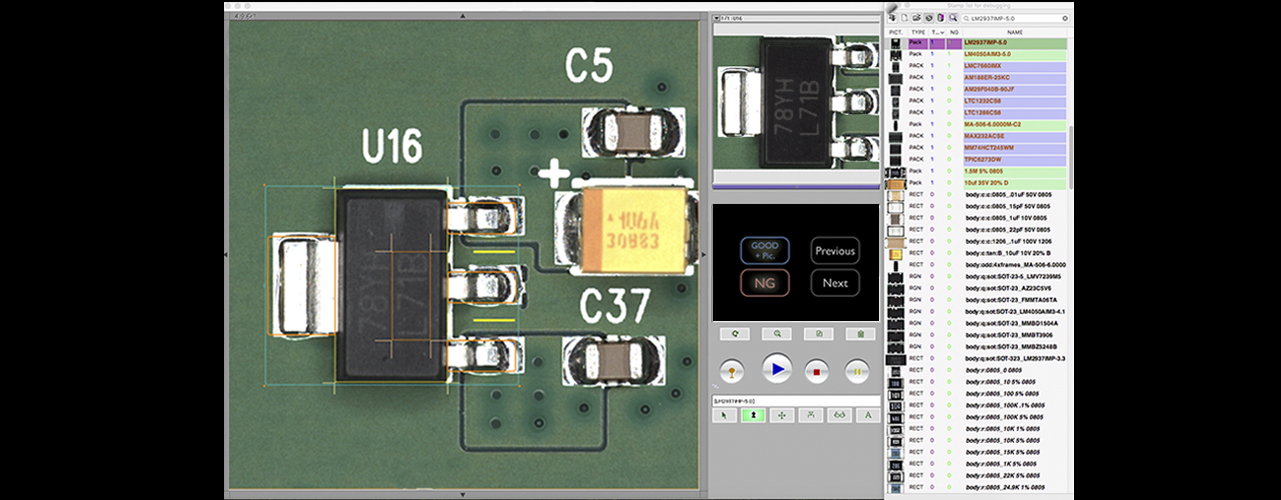

AUTOMATIC OPTICAL INSPECTION (AOI)

In order to verify the correct placement of all SMT components, MEDCO has implemented AOI to inspect for:

• Component placement

• Solder joint defects

• Solder balls and bridging

• Part marking verification

• Polarity and orientation

• Tombstoning / Head-in-pillow.

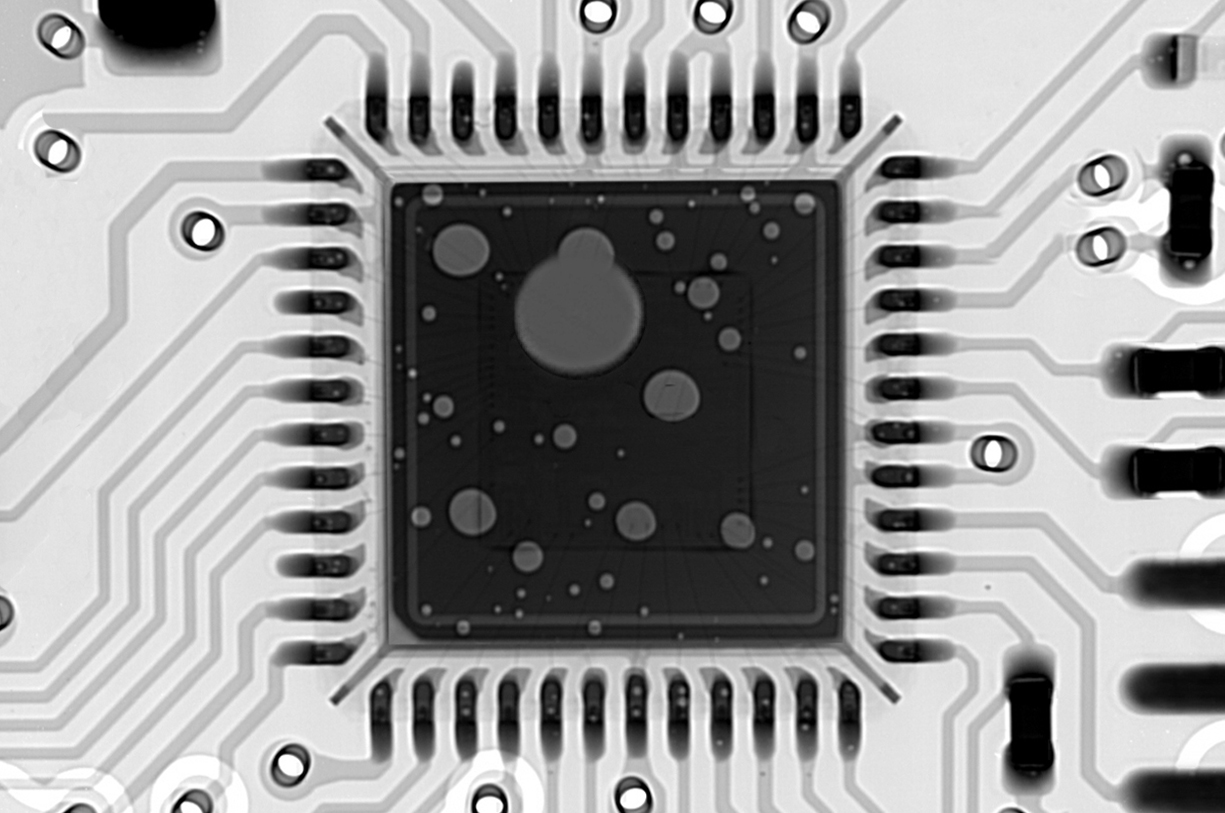

X RAY INSPECTION

MEDCO utilizes X-Ray Technology to verify the solder joint integrity. Components such as BGAs, FPBGAs, QFNs, LEDs, etc., are examined to ensure proper wetting and voiding criteria. We also provide stand-alone X-Ray services to our industry.

IONOGRAPH (IONIC CONTAMINATION TEST SYSTEMS)

MEDCO can test your boards to ensure their compliance with J-STD-001 cleanliness standards.